Resources

Fall Protection Equipment for Offshore, Oil & Gas Industries

Offshore, oil and gas industries are dangerous for workers if the correct safety procedures and equipment are not in place. According to Offshore, Ill Health and Incident Statistics published by HSE, injuries from slips, trips and falls, including falls from heights, account for 52% of all major injuries at offshore sites, particularly where fall protection equipment is inadequate.

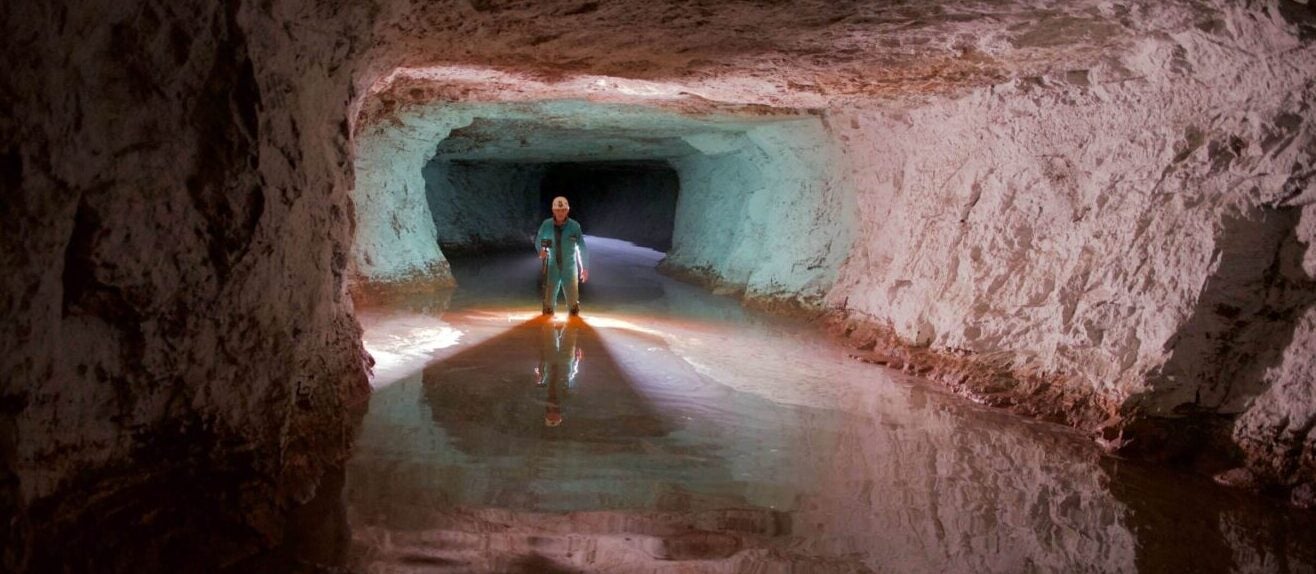

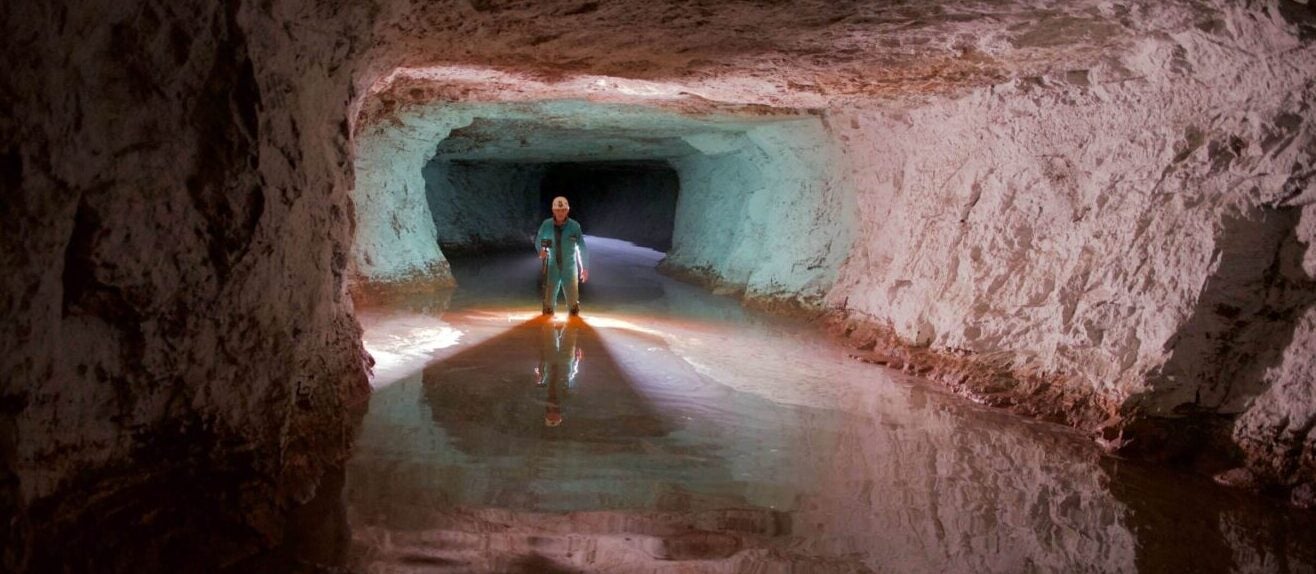

Mine Collapses in North America

There should be no compromise when it comes to mining safety, and mining accidents in the past are unfortunate proof of the importance of finding the best safety equipment and closely following regulations set out by governing bodies such as Mine Safety and Health Administration (MSHA). Looking back at mine collapses can be harrowing, especially when mineworkers have lost their lives, but if the industry is going to protect miners in the future, it is imperative that we learn from the mistakes of the past.

How Efficient Underground Communication Ensures Miners’ Safety and Increases Productivity

“Communication is key” is not a mere platitude, but something that rings true even when working in the most adverse mining environments. Effective communication at mining sites, whether it is using fixed phones, radios or sending tracking data to a central control station, ensures that mines can be safely and effectively managed. The whereabouts of workers, vehicles and various zones across the mine can be monitored, everyone at the site will know where they must be or must go, progress can be assessed and optimised, and risk can be mitigated by providing alerts and communicating with workers should a critical event occur.

GPS and the Mining Industry

For any application of GPS in mining, the aim is to improve productivity and safety. Global positioning systems are useful for a range of tasks, from fleet management to surveying to collision avoidance.

Mining Slurry Technology for Treating Industrial Wastewater

Dewatering at mines and industrial sites can be a tricky task, not only requiring robust, heavy-duty mining slurry technology that can handle abrasive materials and debris (preferably with minimal to no regular maintenance requirements), but also removing and treating this mining wastewater effectively.

MSHA Powered-Haulage Regulations: All You Need to Know

Keeping up to date with new requirements and safety procedures is an essential part of keeping mines safe. In fact, MSHA training programs include retraining on at least an annual basis to ensure that regulations are being followed and that equipment is being used correctly. Last year saw the highest rate of fatalities as a result of powered haulage equipment since 2006. MSHA stepped in to assess why this was happening and put new regulations in place to keep mine workers safe. On this page, you will find regular updates on news about powered haulage equipment requirements.

Industry-Leading MSHA Cordless Mining Light: Polaris NLT vs WISDOM Lights

While both NLT and WISDOM provide effective MSHA-approved cordless mining lights, it is the NLT Polaris that remains the world’s number one cap light. The Polaris was the first intrinsically safe (IS) cap lamp on the market, gaining IECEx, ATEX, and MSHA certification, but what keeps it ahead of the competition to this day?

What Equipment Do You Need for Gold Mining?

Underground hard-rock mining relies on much of the same equipment regardless of the products that are being extracted. Various underground mining techniques are used to excavate ore that contains metals such as gold, silver, iron or copper.

Underground Mine Dewatering Techniques

For many mining sites, controlling the flow of water and removing it from certain areas of the mine is an ongoing challenge. For underground mines, infiltration and potential flooding is a greater risk if the mine extends below the water table.

MSHA Powered Haulage Equipment Safety Guidance

Safety in mining operations demands constant vigilance and adherence to best practices, particularly when it comes to powered haulage equipment. With its inherent risks, this equipment requires careful management to protect lives and maintain efficient operations.

GET IN TOUCH

Contact us now for expert advice, an immediate quote and same-day shipping

Contact us