Collision Avoidance Systems, Devices & Equipment in the Mining Industry

Collision avoidance in and around mining operations is an important concern for mines: collisions between workers and vehicles or machinery are one of the leading causes of serious accidents in the US mining industry.

GET IN TOUCH

Contact us now for expert advice, an immediate quote and same-day shipping

Contact us

Effective Collision Prevention Systems

An effective collision prevention system is an essential part of any modern industrial operation that prioritizes the safety of its workforce.

MSHA Powered-Haulage Regulations: All You Need to Know

Keeping up to date with new requirements and safety procedures is an essential part of keeping mines safe. In fact, MSHA training programs include retraining on at least an annual basis to ensure that regulations are being followed and that equipment is being used correctly. Last year saw the highest rate of fatalities as a result of powered haulage equipment since 2006. MSHA stepped in to assess why this was happening and put new regulations in place to keep mine workers safe. On this page, you will find regular updates on news about powered haulage equipment requirements.

Forklift Collision Avoidance Systems and Proximity Detection

The safety in a warehouse is high priority. According to the Bureau of Labour Statistics, a worker died every 111 minutes from a work-related injury in 2020, of those 30% due to transport-related accidents. Forklifts are powerful and heavy pieces of equipment, to prevent fatalities collision avoidance and proximity alert systems need to be installed.

Proximity-monitoring systems and solutions can significantly reduce these accidents.

Here at Carroll Technologies, we combine the latest innovations with best in class customer service to give you a complete collision mitigation systems solution suitable for mines, tunneling, steel, construction and other industrial projects.

Collision Avoidance: Tracking Solutions

How does a collision avoidance system work? The basis of most collision avoidance solutions is an effective tracking system, which can monitor the positions of workers and pieces of equipment to ensure they don’t come into contact with one another.

This can take the form of tags, worn by workers and attached to machinery and vehicles, which feed information into a control center, ensuring a human operator can see the relative position of everything within a mine, either a surface or underground operation.

These collision avoidance systems also include alarms and alerts that trigger when two tags are moved too close to one another, providing an early collision warning system to prevent accidents from taking place.

These collision detection functions can also be customized, enabling larger or smaller safe zones to be established for individuals and machines of different sizes, creating a system where alarms are tailored to the scale and function of individual operations.

Carroll Technologies adds an additional layer of control to the mining collision avoidance system, with different levels of warning, from yellow to red, to cover a range of threats to worker safety.

Carroll’s MSHA-approved solutions for miner safety include the Miner and Equipment Tracking System which provides tracking, text pager communications and atmospheric monitoring all over a single cable.

Carroll supplies PBE’s PAS Proximity Alert System which utilizes electromagnetic sensors and GPS

This innovative mining collision avoidance system detects light vehicles, heavy vehicles, obstacles and personnel, as well as user-defined geofences.

Ensuring Visibility for Collision Avoidance

Visibility is a key aspect of avoiding collisions, and mine safety in general. This visibility enables personnel to be aware of their surroundings making it less likely to be involved in a crash; tracking systems help provide visibility beyond that which human workers can see with their eyes, improving safety across all operations.

The presence of automatic monitoring and alerts also enables additional visibility without distracting workers, which could compromise personnel or put them in more dangerous situations

“To help minimise those risks, visuals are important in a collision-avoidance system, because you can’t always have visibility on where everything is,” said Carroll engineering president Allen Haywood.

“Let’s say you have a large loader that is moving forward and backward all the time, or loading trucks, a crusher or a loading facility, there’s no way that the operator can see what’s behind him that is in close proximity.”

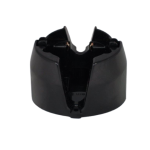

2. The dash-mounted PAS-Z Proximity Alert System (pictured below) alerts drivers to the presence of personnel, vehicles and obstacles. It helps manage vehicle interactions by reporting reliable information on the proximity of the closest objects.

Satellite Technology and Collision Avoidance Sensors

The same principle of proximity monitoring in order to create safe work zones around people and machinery can be scaled up to use satellite technology, to provide a top-down view of surface mining operations.

While satellite solutions require companies to have access to this level of technology, they can save on operational costs and minimize equipment usage in the long-term.

For large-scale, established operations in particular, the use of satellite tracking systems could be a significant and welcome technological upgrade that incorporates several systems into a single operation.

Comprehensive services are increasingly popular in the mining industry, with companies such as Carroll offering tracking and communication services using the same technological base, and could significantly reduce the likelihood of collisions.

Further reading: How does a collision avoidance system work in Mining Operations?

See also: Collision Prevention Systems in Industrial Applications & Mining Safety Equipment & Supplies

Read more: Mining risks and hazards

GET IN TOUCH

Contact us now for expert advice, an immediate quote and same-day shipping

Contact us