Knowledge Hub

Find out more about the industry-leading services Carroll Technologies provides to the mining, steel, construction and tunneling industries in the US.

Our focus is around safety, electrical installations and communications. We carry a vast range of products available for same-day despatch and are able to service and repair everything we supply.

GET IN TOUCH

Contact us now for expert advice, an immediate quote and same-day shipping

Contact us

Respiratory Protection for Energy Transition Workers: Meeting OSHA Standards

In the rush to build a greener future, we cannot overlook the hazards that energy transition workers face, whether it’s inhaling silica dust on solar farms, fumes from battery chemicals, or residual gases in decommissioned fossil fuel sites. The Occupational Safety and Health Administration (OSHA) has set strict standards for respiratory protection, but compliance means more than ticking boxes. It means choosing the right equipment, training workers properly, and preparing for the unexpected.

Harnessing Synthetic Rope for Enhanced Trenchless Tunneling Safety

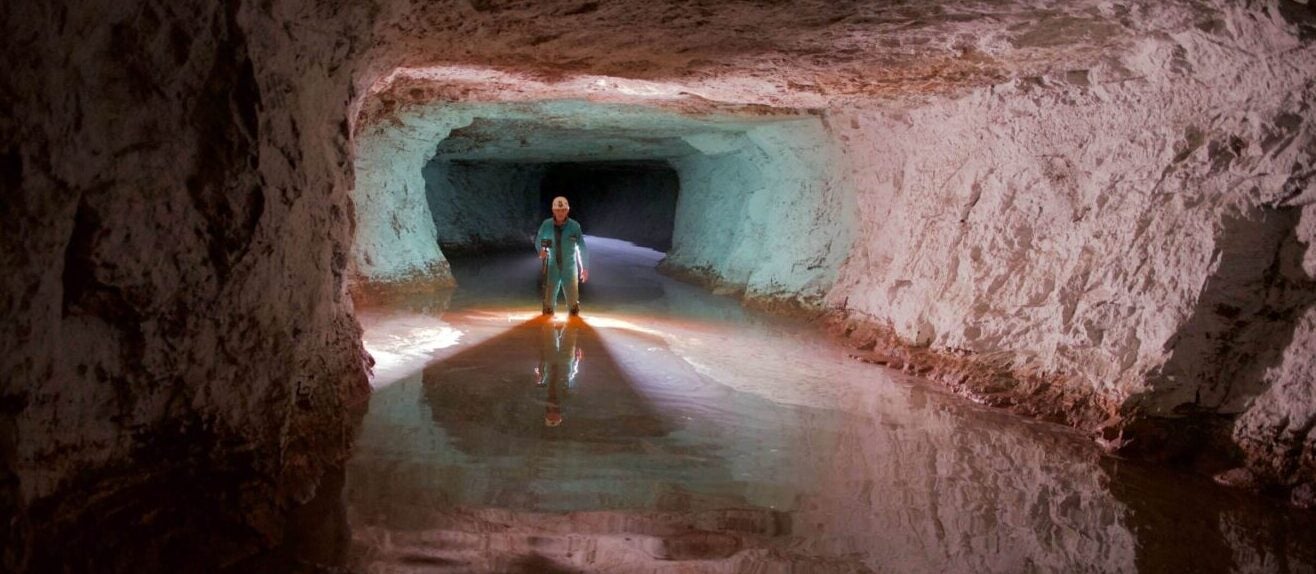

Trenchless tunneling technology offers a safer and more efficient alternative to traditional open-cut methods. However, the complex nature of tunneling operations still demands the highest safety standards to mitigate risks associated with equipment handling, worker safety, and structural integrity.

What’s Ahead for MSHA in 2025

MSHA oversees more than 322,000 miners at 12,600 mines nationwide. By law, MSHA must inspect every underground mine at least four times per year (and every surface mine twice). The agency pairs mandatory inspections with targeted programs, such as its monthly impact inspections at high-violation mines in 2023. These enforcement and outreach efforts appear to be bearing fruit: mining fatal accidents fell by about 30% in 2024, and no U.S. mine met criteria for a “pattern of violations” referral in the latest 2025 screening.

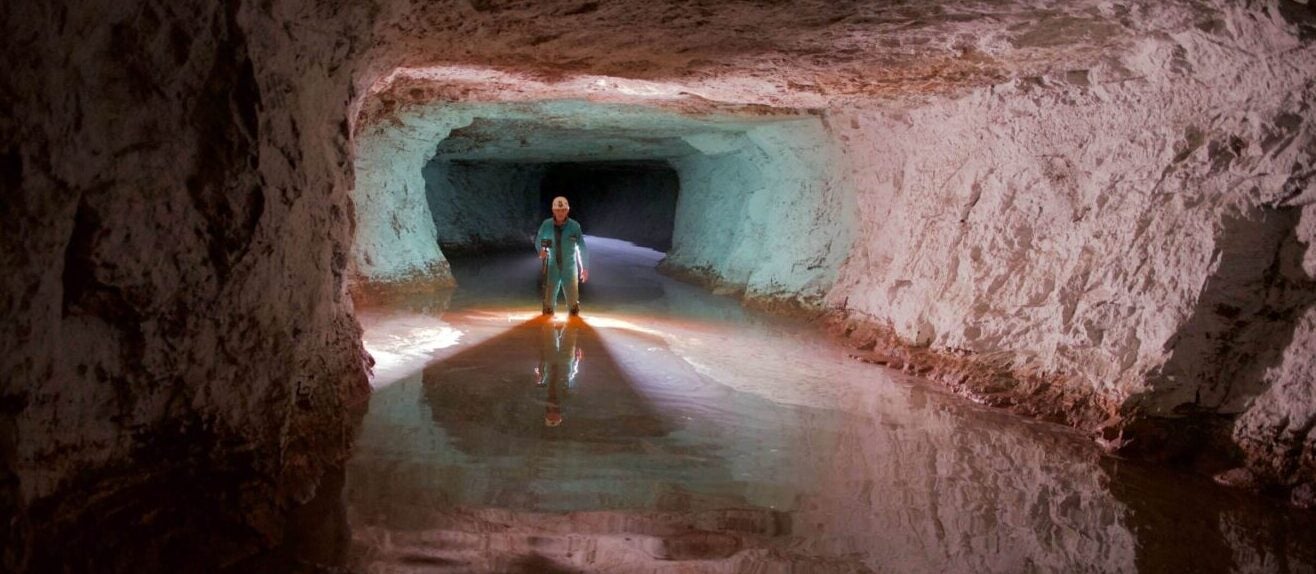

Advanced Trenchless Communications Systems to Enhance Tunneling Safety and Efficiency

Trenchless tunneling techniques, such as horizontal directional drilling (HDD), microtunneling, and pipe jacking, offer significant advantages over traditional excavation methods by reducing surface disruption, minimizing environmental impact, and enhancing overall project efficiency. However, these innovative methods also present unique communication challenges due to their subterranean, remote, and often harsh working conditions.

Fall Protection for Offshore Wind and Large-Scale Solar Farms

With clean energy innovation comes new challenges, particularly regarding safety. Workers on offshore wind turbines and large scale solar farms face unique fall hazards that demand rigorous protection strategies. As renewable energy infrastructure scales up, ensuring comprehensive fall protection is essential.

Portable Communication Systems for Mines, Tunnels, and Rescue Operations: The Sybet Advantage

In challenging underground environments where reliable, real-time communication is critical, fixed infrastructure isn’t always available, or even possible. That’s where Sybet’s portable underground communication systems, supplied exclusively in the US and Canada by Carroll Technologies Group, offer a life-saving solution.

Essential Safety Equipment for Trenchless Tunneling Projects

Trenchless tunneling has transformed the way underground infrastructure projects are carried out, offering a safer, faster, and more efficient alternative to traditional open-cut methods. However, despite its advantages, trenchless technology still poses significant risks, and worker safety should remain a priority.

The Top OSHA Green Job Hazards in Large Energy Transition Projects and How to Prevent Them

As the global push toward net-zero emissions accelerates, the green energy sector is experiencing unprecedented growth, and jobs in solar, wind, hydrogen, and battery storage sectors are booming. While these positions offer promising benefits for the future of sustainability, workers face significant safety hazards that must be proactively managed to ensure this green transition remains truly sustainable.

Silent Seal Mine Foam

Silent-Seal® VCF is a low-pressure, two-component polyurethane foam sealant developed by ICP Group under the HandiFoam brand. Designed specifically for the mining industry, this advanced foam addresses a critical need for effective, long-lasting air seals in mine ventilation systems. Proper ventilation not only ensures breathable air for workers but also plays a key role in controlling hazardous gases, dust, and temperature levels in confined mining environments.

Innovations in Industrial Rope Technology: High-Quality, Industrial-Strength Solutions You Can Trust

Whether for mining, maritime, energy, or rescue applications, the demand for high-performance ropes has never been greater. Samson Rope, a company renowned for pioneering advancements in synthetic rope technology, is at the forefront of meeting this demand.

PPE Requirements

High-risk energy transition projects, such as carbon capture and storage (CCS), offshore wind farms, and hydrogen production, often take place in extreme environments where worker safety is paramount.

Carroll Technologies Group to Exhibit at PDAC 2025 in Toronto

Carroll Technologies Group is excited to announce our participation in PDAC 2025, the world’s premier mineral exploration and mining convention. This prestigious event will take place from March 2-5, 2025 at the Metro Toronto Convention Centre in Toronto, and we are thrilled to exhibit for the first time since expanding our operations into Canada.

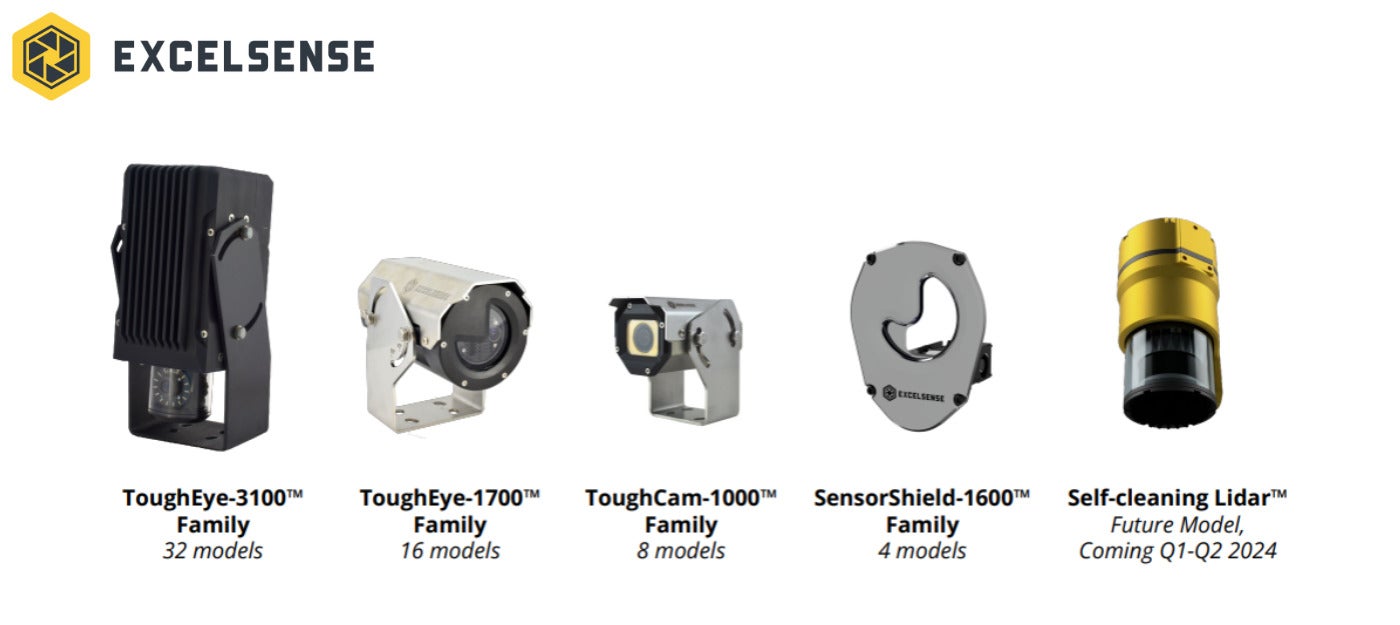

Ensuring Clear Visibility in Harsh Environments with ExcelSense Self-Cleaning Camera Solutions

From ensuring worker safety to optimizing operational efficiency, cameras play a critical role in monitoring processes. However, these devices often face the relentless challenge of harsh environmental conditions. Dirt, debris, extreme temperatures, and moisture can compromise their performance, risking costly downtime and safety breaches.

Advanced Mine Camera Solutions: Top Features to Look for in High-Performance Mine Cameras

In the mining industry, where harsh conditions and environmental hazards are the norm, reliable visibility is crucial for maintaining safety and operational efficiency. Mine cameras play a critical role in monitoring processes, enhancing situational awareness, and supporting autonomous systems.

Carroll Technologies Group vs United Central Industrial Supply: What Sets Carroll Technologies Apart

When it comes to supplying the mining and industrial sectors with reliable, high-quality equipment and services, both United Central Industrial Supply and Carroll Technologies Group have established themselves as trusted names in the industry. While both companies share a dedication to supporting the safety, efficiency, and success of their customers, each brings unique strengths to the table.

Nuclear Reactor and Power Plant Safety Equipment

Safety equipment in nuclear reactors and power plants is essential for ensuring a safe working environment. From PPE and emergency rescue equipment to communication systems that keep staff informed and connected, each piece of equipment serves a critical function in reducing operational risks.

Self-Cleaning Cameras for Mining, Construction and Heavy Industries

In high-demand environments such as mining, construction, and other heavy industries, reliable visibility is critical to ensuring both operational safety and productivity.

High-Quality Portable Rescue Stretchers for Emergency Response Above Ground or In Confined Spaces

When emergencies strike in difficult environments—whether in confined spaces, rugged terrains, or high-traffic areas—response teams need agile, reliable, and efficient equipment to ensure the rapid and safe evacuation of casualties.

Overcoming the Mine Phone Shortage: Why PBE’s GEN II Page Boss Outshines Competitors Amidst Supply Chain Challenges

The mining industry is currently facing a significant shortage of critical communication devices, particularly mine phones. Although the exact reasons for the shortage are unclear, they likely stem from a broader issue in acquiring essential components.

MSHA’s New Silica Dust Rule: What It Means for the Mining Industry

As part of its mission to improve miner health and safety, the Mine Safety and Health Administration (MSHA) has issued a groundbreaking rule aimed at reducing exposure to respirable crystalline silica (RCS).

Mine Safety Equipment Suppliers in the US and Canada

Ensuring the safety of miners is a paramount concern in the mining industry. When it comes to choosing safety equipment, it can be challenging to navigate the market and find the highest quality solutions that are best suited to your requirements.

Lighting Solutions for the Agriculture & Forestry Industry

In agriculture and forestry, lighting is essential for various tasks, including operating machinery, conducting inspections, and ensuring the safety of workers. Proper illumination helps prevent accidents, reduces fatigue, and enhances the overall efficiency of operations.

Water Management: Best Pumps for the Agriculture & Forestry Industry

Water management is a critical component in both agriculture and forestry, industries that rely heavily on efficient and reliable irrigation systems. Choosing the right pump can significantly impact the sustainability and productivity of these sectors.

Leading AMOT Industrial Equipment Safety & Control Valves Distributors in North America

Control valves are essential in regulating the flow of liquids and gases within various industrial systems. They are crucial in maintaining optimal operating conditions, preventing equipment damage, and ensuring safety. AMOT control valves are designed to meet the rigorous demands of industrial applications, providing precise control, reliability, and safety.

Buggy Whip Vs Competitors: Driver Industrial, 5150 Whips, Tribal Whips, Gecko Whips

In industries where heavy machinery and vehicles are a daily necessity, ensuring the safety of operators and nearby workers is paramount, especially when working in adverse environments. One often overlooked yet crucial component of vehicle safety is the quality of safety whips. These brightly colored, high-visibility whips serve as essential markers, alerting others to the presence of vehicles in busy and hazardous environments.

Alemite Vs Balcrank Fluid Management Solutions

Choosing the right fluid management solution for industrial applications is crucial for ensuring operational efficiency and reliability. Alemite and Balcrank are two major names in the industrial lubrication and fluid management market, both offering a range of solutions designed to enhance efficiency, accuracy, and reliability in fluid handling.

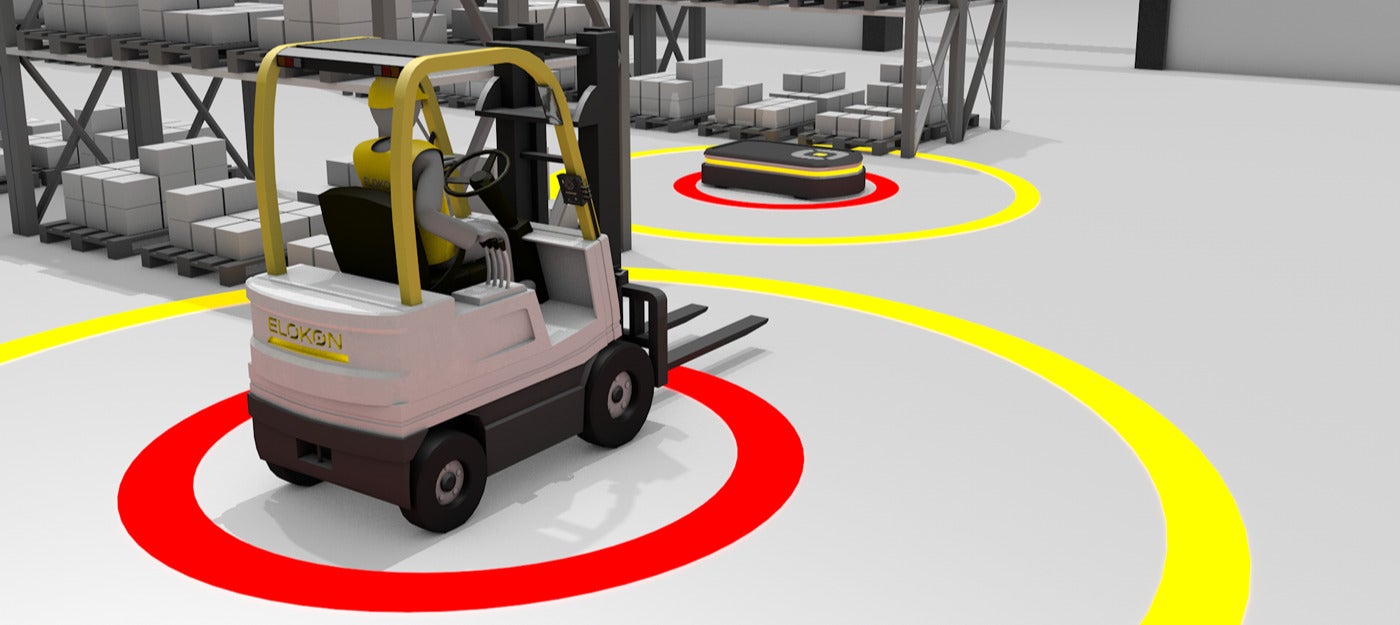

How ELOKON and Carroll Technologies’ Strategic Distribution Partnership Will Enhance Industrial Safety

ELOKON, a global leader in advanced safety and fleet management systems for industrial vehicles, has announced its strategic partnership with Carroll Technologies Group, the leading provider of safety and communication equipment to several important industrial sectors.

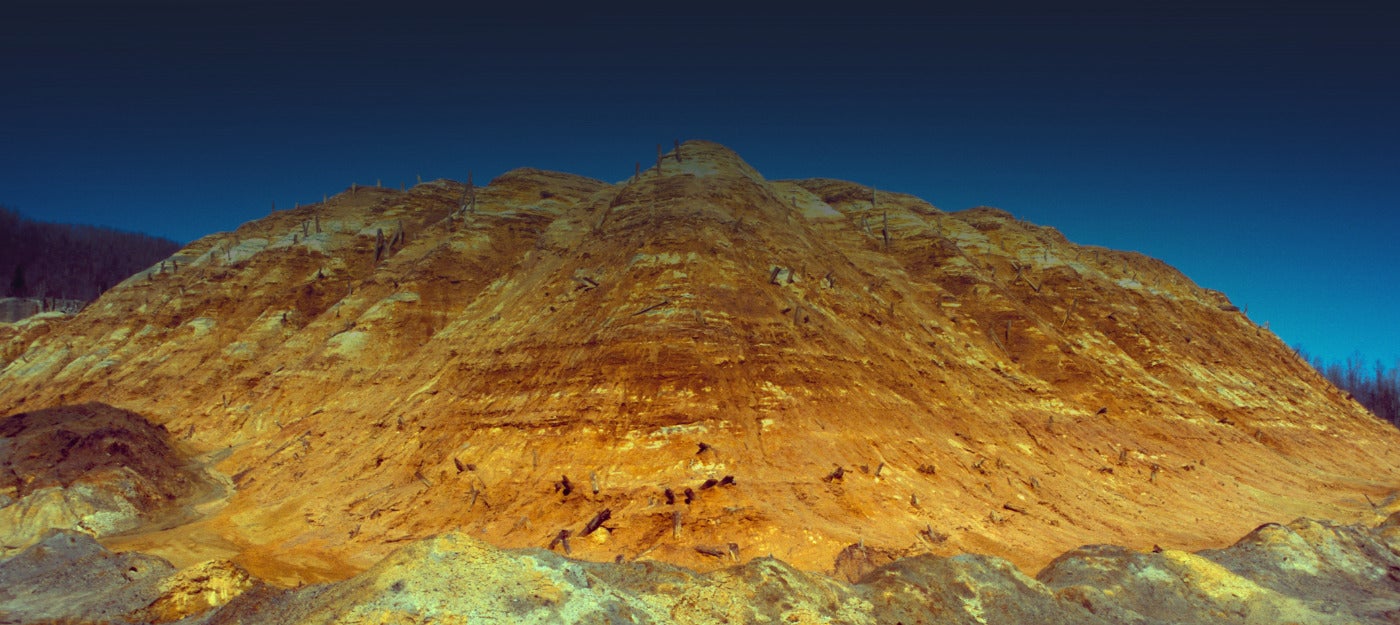

Mine Collapses in Canada: Preventative Safety Solutions

On May 10, 2024, a mine in northern Ontario, Canada, suffered a significant collapse, resulting in the tragic loss of lives and causing a major disruption in the local economy. This incident highlighted the critical need for improved safety measures in the Canadian mining industry and why preventative safety solutions are needed to mitigate the risk of mine collapses.

Wilden vs SAMOA Industrial Pumps

Selecting the right pump for specific applications is crucial for ensuring operational efficiency and reliability. Wilden and SAMOA are two prominent names in this industry, each with its own strengths and offerings.

Where to Buy Samson Rope Solutions in Canada

Samson Rope stands as a premier manufacturer of synthetic rope products in Canada, proven in the field and trusted across various demanding industries. Their ropes are integral for applications including climbing, rigging, crane operations, conveyor belt pulling, and safety and rescue missions.

Sewer Safety Equipment and Solutions

Sewer maintenance is a critical yet hazardous task, necessitating stringent safety measures and specialized equipment to protect workers from the multitude of risks associated with working in confined spaces. These dangers range from exposure to toxic gases to the risk of drowning or being caught in machinery. Adhering to the Occupational Safety and Health Administration's (OSHA) regulations is paramount to ensuring worker safety.

Stored Oxygen vs Breathable Air: Choosing Between MSA’s W65 Self-Rescue Respirator and Ocenco’s M20 or EBA6.5

In industries where workers are exposed to hazardous environments, personal safety devices are crucial. Among these, self-contained self-rescuers (SCSRs) are essential for providing breathable air in the event of an emergency.

Grease Hoses for Use in Construction, Mining, Oil and Gas and Other Heavy Industries

In the demanding environments of construction, mining, oil and gas, and other heavy industries, the efficiency and reliability of machinery are paramount.

Top Suppliers of Gold Mining Safety Equipment in Canada

Canada is the fourth-largest producer of gold in the world. Gold mining inherently comes with various risks, from exposure to hazardous substances to physical dangers associated with underground environments. To mitigate these risks, gold mines across Canada look for the top suppliers of safety equipment, from PPE to efficient lighting solutions.

Leading Suppliers of Respirators in Canada

As leading suppliers of respirators in Canada, MSA offers a broad range of innovative products designed to protect workers across various industries. With its long history, MSA has evolved from its initial focus on mine safety to becoming a global leader in the development and manufacture of safety products. In Canada, MSA's reputation is built on a foundation of reliability, innovation, and unwavering commitment to protecting workers' health and safety.

Pipeline Safety Equipment and Solutions

The Pipeline and Hazardous Materials Safety Administration (PHMSA) plays a crucial role in setting and enforcing regulations to ensure the safe transport of energy and hazardous materials across the United States.

Microtunneling Safety Equipment for Sewers, Pipelines and Other Infrastructure Projects

Microtunneling operations, while less intrusive on the surface, pose significant risks to operators and the machinery due to the confined spaces, underground uncertainties, and the complex machinery involved.

Cost Effective Mine Safety Solutions for Avoiding Collisions

Collision avoidance solutions represent a vital component of modern mining operations, offering the potential to significantly reduce risks and enhance efficiency.

Where to Buy Harrington Hoists

High-quality hoists are indispensable for mining operations, and Harrington Hoists stands as a premier supplier across the US, offering an extensive range of lifting solutions tailored for the mining sector and various other industries.

Optimize Your Mining Operations With Our Premium Material-Handling Equipment Solutions in Canada

Material handling equipment plays a pivotal role in ensuring the safe and efficient transport and storage of goods throughout the manufacturing and distribution stages. Canadian facilities often employ a blend of fixed and variable path transportation solutions, including advanced conveyor systems and versatile cranes and trucks, to meet their operational needs.

Mining Equipment Suppliers in Canada: Reliable and Efficient Mine Safety Solutions

Canada boasts a rich history in the mining industry, making it one of the world's leading mineral resource producers. The success of this sector owes much to the cutting-edge equipment and technology supplied by numerous companies across the country.

Top Suppliers of Buggy Whip Safety Whips in the US and Canada

The Buggy Whip brand is synonymous with high-quality safety whips, providing LED safety antennas that competitors have been unable to match to this day.

Where to Buy Honeywell Safety Products in Canada

Honeywell Safety Products provides a comprehensive range of safety solutions, including gas detection systems, hearing protection, fire safety systems, and personal protective equipment (PPE).

Pneumatic Diaphragm Pumps: Robust and Versatile Industrial Pumping Solutions

Pneumatic diaphragm pumps are a type of positive displacement pump that uses compressed air as the driving force. They are characterized by their unique design, which includes a flexible diaphragm that moves back and forth to create a pumping action.

Electrical and Electronic Equipment from Top Mining Electrical Companies

Here at Carroll Technologies Group, we understand the necessity for safety, improved productivity and efficiency across industrial applications. Because of this, we proudly supply a comprehensive range of electrical and electronics equipment from industry-leading manufacturers, including Eaton, Benshaw Applied Motor Controls, Line Power, Mining Controls Inc. (MCI), American Electric Equipment Inc. (AEEI), Simpson Meters, and more.

Carroll Technologies Group Expanding Mine Safety Operations into Canada

US Mining Expertise to Benefit Canadian Mines as Carroll Technologies Group Brings Four Decades of Experience North of the Border

Harrington Electric Hoists for Mines, Tunnels & Industrial Applications

Electric hoists for mines and tunneling and industrial applications are relied upon for lifting and transporting heavy loads, so durable and reliable hoists are a must.

Hazard Recognition and Prevention Guidance: Ensuring Workplace Safety

National Safety Month serves as a timely reminder to prioritize the safety and well-being of employees in all industries.

Heat Illness Prevention Guidelines: Protecting Workers During Summer

As temperatures soar during the summer months, outdoor workers face an increased risk of heat-related illnesses.

OSHA’s National Emphasis Program to Prevent Falls: Safeguarding Against Slips, Trips & Falls

In support of National Safety Month's focus on Slips, Trips & Falls, this article highlights the significance of OSHA's National Emphasis Program (NEP) to prevent falls.

Benshaw Applied Motor Controls in the Aerospace Industry

In the fast-paced world of aerospace technology, efficiency and performance are paramount. Carroll Technologies Group is proud to be a top supplier of Benshaw motor control products.

Safety Benefits of Synthetic Rope vs Wire Rope for Industrial Applications

Synthetic rope and wire rope are both commonly used in industrial applications, but each has its own advantages and disadvantages. In recent years, synthetic rope has gained popularity over wire rope due to its superior safety benefits.

Top 10 OSHA Violations – How Carroll Technologies Group Can Help to Prevent Health and Safety Hazards in Industrial Settings

The Occupational Safety and Health Administration (OSHA) enforces regulations aimed at maintaining safe and healthy working conditions in the United States.

Carroll Launches Collision Avoidance Alert Campaign

Carroll Technologies has launched a campaign to reduce the death toll from non-roadway collisions at US mines, construction and other industrial sites.

Commercial Vehicle Collision Avoidance Systems

Commercial vehicles manoeuvring around and travelling to construction sites, mining facilities, and other busy industrial locations need to be part of a vehicle collision avoidance system. Even on the road, large commercial conveyances should have proximity sensors for vehicles.

Collision Avoidance Systems for Cranes

Collision avoidance systems for cranes are essential for keeping workers safe. According to the US Bureau of Labor Statistics, the Census of Fatal Occupational Injuries (CFOI) reported 297 crane-related deaths between 2011 and 2017, 157 of which involved the worker being struck by an object or equipment.

Substations for Mining, Tunneling and Dredging Applications

Effective distribution, control, and transmission of electricity at a mining site is an essential part of ensuring that operations run smoothly and safely. Power from a central station will require a mining or tunnel substation to supply direct current to operate electrical equipment by transforming high voltages to direct current at 250 or 500 volts.

Forklift Collision Avoidance Systems and Proximity Detection

Warehouse safety is a top priority, and the risks posed by operating heavy machinery such as forklifts cannot be underestimated. According to the Bureau of Labor Statistics, a worker died every 111 minutes from a work-related injury in 2020, with 30% of those fatalities linked to transport-related accidents. Forklifts are powerful and heavy pieces of equipment, and installing a forklift collision detection system is essential for preventing accidents and saving lives.

Communication Solutions for the Energy Industry

Effective communication solutions for the energy industry are key to ensuring that operations run smoothly and that any problems are corrected quickly should they arise.

Confined Space Safety in Power Plants

Confined spaces in power plants are often considered one of the most dangerous types of work performed in that setting. The risks have been recognized by companies and safety precautions are put in place to ensure these hazardous conditions are safer for workers.

Fall protection equipment for the energy, power and utilities industries

For Carroll Technologies, providing workers with the best fall protection equipment is a key priority.

Offshore Fire Safety Systems

The hazards of being on an oil rig every day are very real. There is a chance that fires can occur and it is essential to reduce the breakout of the blaze. With the proper fire suppression systems in place it will help to keep the workplace safer, savings lives and minimizing damage done to the machinery in the process.

Confined Space in Oil and Gas Industry: Safety Solutions

The offshore industry can be dangerous as there are times where workers will need to be in confined spaces. There are various risks that are involved such as build up of noxious fumes, reduced oxygen levels, or a risk of fire.

Respirators Used in the Offshore, Oil and Gas Industry

It's no surprise the offshore industry is dangerous and work-related hazards are common for workers on the rig. Personal protection equipment such as respirators help to protect against particles, gases and vapors.

SMI Ground Control in Mining

Mining as an industry can be a hazardous environment to work in, making ground control procedures essential for the safety of the workers. These devices will constantly monitor the ground making the presence of any danger immediately clear to mine personnel in the area.

PPE for the Oil and Gas Industry

The oil and gas industries average a fatality rate seven times greater in comparison to the rate for all U.S. industries (25.1 compared with 3.7 per 100,000 per year). The workers face hazards throughout their daily duties, which is why its necessary for employers to provide them with the correct personal protective equipment.

Mine Falls: How to Prevent and Predict Roof Collapses

The correct safety precautions need to be taken to prevent the roof from collapsing inside a mine.

Fall Protection Equipment for Offshore, Oil & Gas Industries

Offshore, oil and gas industries are dangerous for workers if the correct safety procedures and equipment are not in place. According to Offshore, Ill Health and Incident Statistics published by HSE, injuries from slips, trips and falls, including falls from heights, account for 52% of all major injuries at offshore sites, particularly where fall protection equipment is inadequate.

Mine Collapses in North America

There should be no compromise when it comes to mining safety, and mining accidents in the past are unfortunate proof of the importance of finding the best safety equipment and closely following regulations set out by governing bodies such as Mine Safety and Health Administration (MSHA). Looking back at mine collapses can be harrowing, especially when mineworkers have lost their lives, but if the industry is going to protect miners in the future, it is imperative that we learn from the mistakes of the past.

How Efficient Underground Communication Ensures Miners’ Safety and Increases Productivity

“Communication is key” is not a mere platitude, but something that rings true even when working in the most adverse mining environments. Effective communication at mining sites, whether it is using fixed phones, radios or sending tracking data to a central control station, ensures that mines can be safely and effectively managed. The whereabouts of workers, vehicles and various zones across the mine can be monitored, everyone at the site will know where they must be or must go, progress can be assessed and optimised, and risk can be mitigated by providing alerts and communicating with workers should a critical event occur.

GPS and the Mining Industry

For any application of GPS in mining, the aim is to improve productivity and safety. Global positioning systems are useful for a range of tasks, from fleet management to surveying to collision avoidance.

Mining Slurry Technology for Treating Industrial Wastewater

Dewatering at mines and industrial sites can be a tricky task, not only requiring robust, heavy-duty mining slurry technology that can handle abrasive materials and debris (preferably with minimal to no regular maintenance requirements), but also removing and treating this mining wastewater effectively.

MSHA Powered-Haulage Regulations: All You Need to Know

Keeping up to date with new requirements and safety procedures is an essential part of keeping mines safe. In fact, MSHA training programs include retraining on at least an annual basis to ensure that regulations are being followed and that equipment is being used correctly. Last year saw the highest rate of fatalities as a result of powered haulage equipment since 2006. MSHA stepped in to assess why this was happening and put new regulations in place to keep mine workers safe. On this page, you will find regular updates on news about powered haulage equipment requirements.

Industry-Leading MSHA Cordless Mining Light: Polaris NLT vs WISDOM Lights

While both NLT and WISDOM provide effective MSHA-approved cordless mining lights, it is the NLT Polaris that remains the world’s number one cap light. The Polaris was the first intrinsically safe (IS) cap lamp on the market, gaining IECEx, ATEX, and MSHA certification, but what keeps it ahead of the competition to this day?

What Equipment Do You Need for Gold Mining?

Underground hard-rock mining relies on much of the same equipment regardless of the products that are being extracted. Various underground mining techniques are used to excavate ore that contains metals such as gold, silver, iron or copper.

Underground Mine Dewatering Techniques

For many mining sites, controlling the flow of water and removing it from certain areas of the mine is an ongoing challenge. For underground mines, infiltration and potential flooding is a greater risk if the mine extends below the water table.

MSHA powered haulage equipment safety guidance

Safety in mining operations demands constant vigilance and adherence to best practices, particularly when it comes to powered haulage equipment. With its inherent risks, this equipment requires careful management to protect lives and maintain efficient operations.

Collision Warning Systems in Mining

Surface and underground mining involve a lot of heavy-duty vehicles that can pose a threat to personnel in the event of a collision, as well as risking costly repairs and downtime. With so many moving parts, even effective management and skilled operators cannot ensure that risk is minimized, especially in adverse environments.

The Importance of Education in Mining Safety

If there is one factor that stands above all else for mine operators, it is mining safety. It is no wonder that the mining safety market is thriving, with operators eager to invest in protecting their workers, as well as protecting expensive equipment.

MSHA-Certified Mining Equipment and Training

From hard hats to fall equipment, communication solutions and circuit breakers, Carroll Technologies is dedicated to being a one-stop-shop when it comes to MSHA-certified machinery and safety equipment.

Koehler Mining Lights Vs NLT

Koehler Mining Lights and Northern Light Technologies (NLT) are two of the leading brands when it comes to cap lights for miners and all those working underground.

Why We Recommend Stancor Pumps

Where to buy Stancor pumps in the USA? Carroll Technologies has just added Stancor to the approved range of products it supplies and can offer a customized, fully-serviced solution.

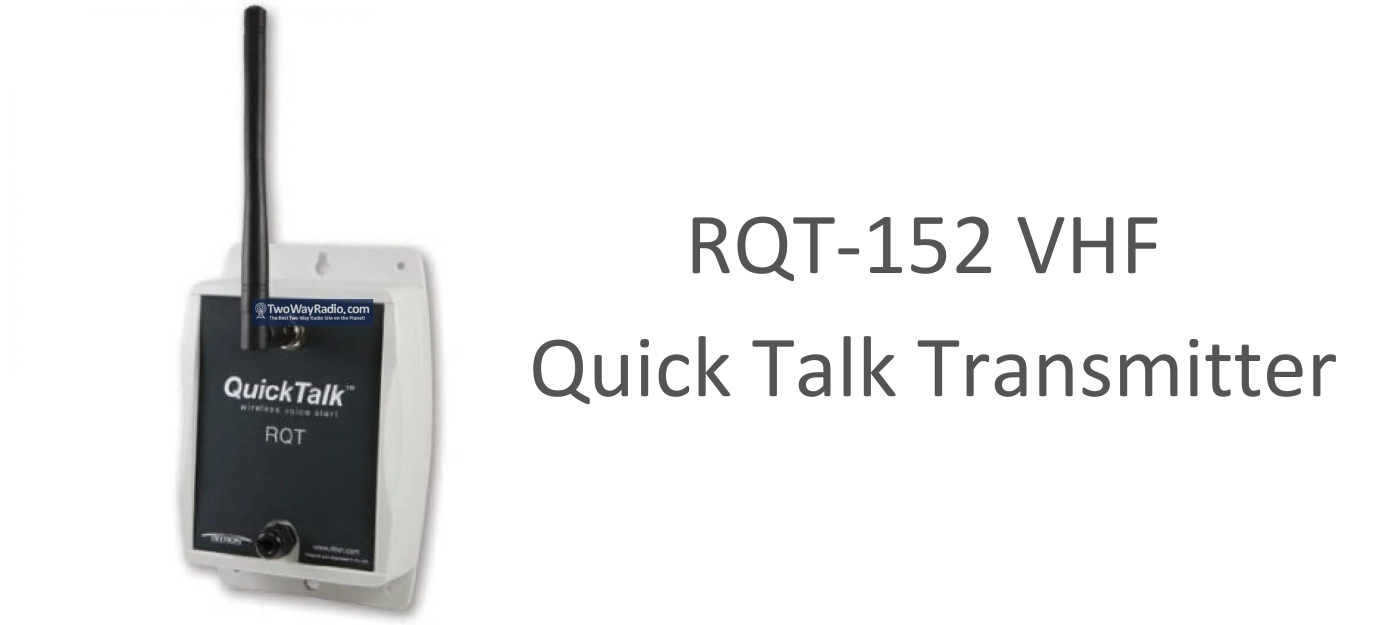

RQT-152 VHF Quick Talk Transmitter for Wireless Alerting

The RQT-152 VHF quick talk transmitter enables wireless alerting over radio systems. If equipped with an optional receiver, the transmitter can be remotely activated by a wireless key FOB or a battery-powered wireless call button.

Eaton Thermal Magnetic Circuit Breaker: A Fail Safe Safety Solution

Eaton’s Thermal Magnetic Circuit Breaker C Series from Cutler-Hammer (a division of Eaton) is the result of years of experience designing solutions that improve electrical safety, efficiency power distribution and code compliance.

Benefits of the NLT Polaris Cordless Cap Lamp

The Northern Light Technologies’ Polaris cap lamp (NL0329) is an award-winning headpiece available with an adjustable or fixed clip. It is the first MSHA-approved all-in-one cordless mining cap lamp.

Mine Process and Service (MPS): Endorsed by Carroll Technologies

Whether you are working at or visiting a mining site, no one can feel safe without a field-proven and robust hard hat. Worker safety is at the core of Mine Process and Service (MPS’s) ethos, and over the last 30 years, the company has worked hard to promote safety and efficiency in the mining industry.

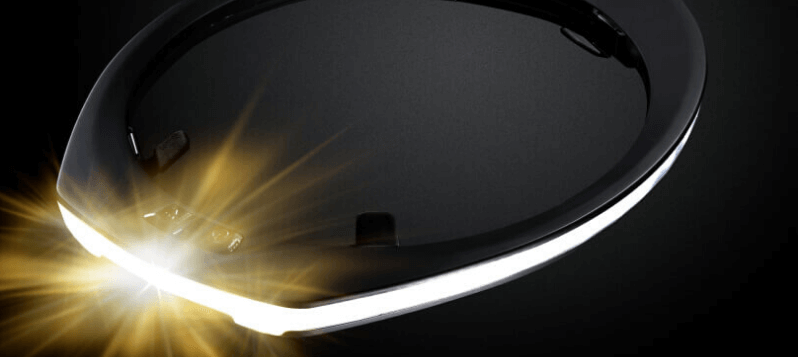

Focus on Illumagear Halo Hard Hat Light

The Halo cap light from Illumagear is a cordless 360° light that can be attached to any standard hard hat. The technology and design behind it ensures for unparalleled visibility for underground operations.

Recovery Slings for Mines and Tunnels: Reducing Manpower Requirements and Safety Hazards

Recovery slings for mines and tunnels (or tow slings) are an essential part of lifting and transporting heavy loads. Strong and effective recovery slings reduce how many workers are required for the application, as well as improving safety and preventing breakages.

Dust Suppression and Control

Dust production in mining and tunneling operations is inevitable, especially when working with heavy equipment. Effective dust suppression products and systems are essential for protecting workers and maintaining equipment efficiency in underground mines and tunnels.

Benefits of Ocenco Self-Rescuers

Dedicated to manufacturing quality safety equipment for hazardous environments, Ocenco is a global provider of emergency escape breathing devices and respiratory safety equipment.

Vision X Offroad: Mobile LED Lighting Solutions Endorsed by Carroll Technologies

Vision X Offroad is a leading supplier of LED lighting for off-road vehicles. These products are used for numerous applications, including lighting solutions for mining and tunnelling operations.

Becker/SMC: Motor Control Solutions for Mines and Tunneling

Becker/SMC designs and manufactures a comprehensive range of electrical components, longwall electrical controls, power distribution equipment and explosion-proof motor starters for a range of industries and applications, including mining and tunnelling operations.

Fire Protection and Safety in Mines, Tunnels & the Water Industry

Dangerous equipment and potentially toxic gasses in underground tunnels makes the mining, tunneling and water industries particularly susceptible to the risk of workplace fires. Fire protection and safety in tunnels is essential.

Robust and Reliable Conveyor Belt Systems for Mines and Tunnels

Robust conveyor belt systems for mines and tunnels enable operations to run smoothly, with throughput being reliably transported between processes. Carroll Technologies distributes conveyor belt systems from a range of trusted manufacturers, including Goro, Mefcor, and PBE Electronics.

Why We Recommend Samson Rope

For more than 140 years, Samson have been developing innovative synthetic rope solutions and providing industry-leading service. Its expertly engineered ropes are manufactured from high-performance fibres, ideal for replacing wire rope.

Pyott Boone Leaky Feeder Systems

Leaky feeder communication systems (or radiating cables) are an effective method of wireless communication between mine workers.

Minegrid Geosynthetic Support

Minegrid (FW35/35-55SUA) is a high-tenacity polyester [PET] and polyvinyl alcohol [PVA] geogrid, which is covered with a flame-resistant, anti-static coating. Designed and produced by Huesker, experts in geosynthetic materials and geogrid retaining walls, Minegrid is offered in tensile strengths ranging from 35kN/m to 1,000kN/m.

Page Boss Mine Phone: A Proven Solution

Effective underground communication is essential for maintaining the safety and efficiency of mining operations, and the Model 112 Page Boss mine phone by PBE Axell (112 GEN II) is one of the most advanced communication devices available to the industry.

Belt Fasteners and Splicing Solutions

Supporting more than 800 mines across North America, Carroll Technologies is an industry leading supplier of industrial and safety products for the mining and tunnelling sector, including a range of conveyor belt fasteners.

Why Carroll is Best for Mine and Tunnell Safety

Carroll Technologies is the number one provider of mining and tunneling safety equipment and safety expertise across North America.

Boost Signal With A Leaky Feeder Amplifier

A leaky feeder system is used to enable communication between mining staff above and below ground over long distances, using both wired and wireless systems. A coaxial cable with sections of outer shielding shaved away allows radio signals to “leak” in and out, transmitting them over long distances.

Federal Pacific: why Carroll Technologies is North America’s Leading Supplier

America’s premier supplier of Federal Pacific mining products: Carroll Technologies provides a customized solution, optimised and integrated with other leading systems.

Mining Controls: Why Carroll Technologies is North America’s Leading Supplier

America’s premier supplier of Mining Controls: Carroll Technologies provides a customized solution, optimized and integrated with other leading systems.

Air Filtration and Dust Collection Briefing

Any operator will know that air quality in tunneling and mining systems must be closely monitored to ensure the safety of its workers. In addition to potentially dangerous gases, abrasive dust particles are an inevitable side effect of most mining and mineral processing applications.

How Rescue Packs Protect Workers

Mining rescue packs are a type of personal safety equipment for underground workers to protect them in case of an emergency incident such as an explosion, mine collapse or gas leak.

Serving Tennessee with DAS Solutions

Public safety DAS systems are designed to support emergency responders to protect the well-being of people in public-use spaces or worksites.

Key Tunnel Safety Systems for Mining Personnel

Working in underground tunnels presents many possible hazards for mining personnel. There is the potential of a fire, becoming trapped or being exposed to poisonous gases. Yet if risks are continuously assessed and monitored, it is possible to greatly improve tunnel safety systems for staff.

The Importance of Effective Breathing Air Systems for Confined Spaces

Any operator will know that air quality in tunnelling and mining systems must be closely monitored to ensure the safety of its workers. In addition to potentially dangerous gases, abrasive dust particles are an inevitable side effect of most mining and mineral processing applications.

Distributed Antenna Systems (DAS) for Mines, Tunnels and Buildings

Connectivity dead zones, unreliable radio range and dropped mobile phone calls are all symptoms of an absence of two-way radio or mobile communications within a space.

How Mining Ventilation Curtains & Systems Keep Miners Safe

Ventilation is an essential measure in underground mining. We take a look at the different types of ventilation systems in mining below and why they are so vital.

Conveyor Belt Monitoring and Control

One of the most important aspects of a successful mining operation is the effectiveness of a project’s conveyor belts, transporting material too bulky and heavy to be carried by hand to where it needs to be, and functioning in a safe manner.

Effective Collision Prevention Systems

An effective collision prevention system is an essential part of any modern industrial operation that prioritizes the safety of its workforce.

GET IN TOUCH

Contact us now for expert advice, an immediate quote and same-day shipping

Contact us